1. Construction and location of your end (terminating) posts

|

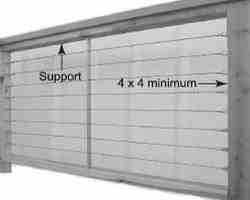

An end post is a post to which terminating cable ends are attached with tensioning or non-tensioning hardware. Considerable tension is applied to the end posts, when the cable is properly tensioned. A substantial end post is necessary, to prevent the end post from bending, which will cause the cables to sag. In wood, a minimum 4x4 (3-1/2” square) end post is required. End posts must be securely fastened to the deck or other surface, to prevent the post from coming loose with the forces applied through the tensioned cables. Support members between end posts are also necessary. In wood, we recommend support members running between posts, such as a 2x4 secured to the inside of each post, so you are not relying on the shear strength of the nails or screws to support the tension applied to the end post. |

2. Configuration of any corners in your design

At corners or turns of more than approximately 45 degrees, it is best to terminate your runs in each direction with an end post (minimum of a nominal 4x4). The following illustrations demonstrate how this is done.

|

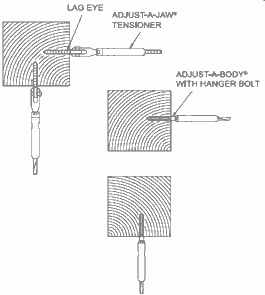

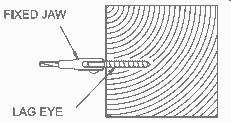

Lag Eye |

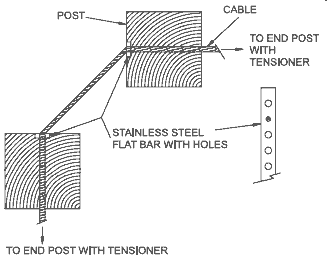

A corner may be designed using two posts on the corner and running the cables between the posts as illustrated below. There must be a tensioner on both ends.

|

A stainless steel flat bar (cable support) with holes for the cable to pass through is mounted on each surface where the cable enters or exits the post at an angle, to prevent the cable from biting into the wood when it is tensioned. Cable supports are available from the factory (see the Wood Accessories section of this publication for order information). We do not recommend using this type of corner post configuration on more than one corner between any two end posts (with tensioning hardware). When using this configuration, you will need tensioning hardware on both ends of the run, and you will need to tension the cables from both ends. On a turn of less than approximately 45 degrees, you can run your cables through a single post, but you will still need to use a cable support where the cable enters or exits the post at an angle, to prevent the cable from biting into the wood when it is tensioned. See No. 8. Selection of appropriate hardware below for other hardware combinations that can be used on corner posts. |

3. Location of intermediate posts

Intermediate posts (or mid-posts) are placed between end posts. An intermediate post runs from the top rail to the lower mounting surface and is a structural element.

Intermediate posts should be placed at intervals between end or corner posts as frequently as necessary to meet building code requirements. An engineer or design professional should be engaged, if you are unable to otherwise determine intermediate post spacing.

Cable is strung through holes drilled in the intermediate posts, so intermediate posts also become supports for the cable between end posts.

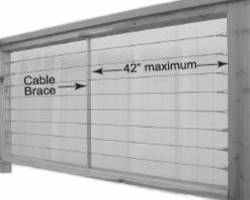

With cable spaced vertically on centers as recommended below (see No. 6 Spacing of cables on your end post), we recommend that the cable be supported in some manner no more than every 48” along its run. The support can be provided by an intermediate post or it can be something thinner such as a 2x4 or a thin steel cable brace (see No. 4 Location of additional cable supports below).

4. Location of Additional Cable Supports

|

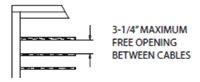

Regardless of the amount of tension you apply to the cables, there will be some flex in the cable when it is installed. When the cables are spaced vertically on your end post as we recommend below (see No. 6 Spacing of cables on your end post), we recommend that the cable be supported in some manner no more than every 48” along its run, to meet code requirements that a 4” sphere cannot pass through the cables. As indicated above, this support can be provided with intermediate posts or a lighter material acting as a cable brace. As with an intermediate post, a cable brace also runs between the top rail and the lower mounting surface, but its purpose is only to support the cable. It is not intended to be an element providing structural support to the railing. Cable braces can be much thinner and, therefore, less obtrusive than posts, as their primary purpose is only to support the cable |

A ¼”x1” steel flat bar, usually stainless steel, with holes drilled for the cables to pass through makes an excellent cable brace. Flat bar cable braces are available from the factory (see the Wood Accessories section of this publication for order information).

5. Cable diameter to use

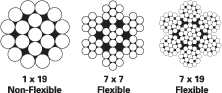

It is important to use 1x19 construction cable as a railing in-fill, because it is attractive, smooth to the touch, and designed to support loads in tension with minimal stretch.

The individual wires in 1x19 construction cable are much larger than those used in more flexible constructions. This makes the cable less prone to damage from abuse, and it is also the reason why strand does not stretch as much as other constructions.

|

You will want to specify type 316 stainless steel, because it is the most corrosion resistant commercially available alloy used in manufacturing cable. Cable Art hardware is made from type 316 stainless steel, so no material compatibility issues will arise when you use type 316 stainless steel cable with Cable Art hardware. It is also important to use at least a 1/8” diameter cable. Problems have been experienced with damage from abuse when smaller diameter cable has been used. Following are minimum breaking strengths for type 316 stainless steel cable. |

Cable Diameter |

1 x 19 |

7 x 7 |

7 x 19 |

1/8" |

1,780 lbs. |

1,360 lbs |

1,300 lbs |

3/16" |

4,000 lbs |

3,300 lbs |

2,900 lbs |

1/4" |

6.900 lbs |

5,500 lbs |

4,900 lbs |

As the chart above illustrates, for a small increase in size (and cost) you can more than double the strength of your in-fill and ensure that damage from abuse is not an issue with your railing.

Everything considered, 1/8” or 3/16” diameter 1x19 construction type 316 stainless steel cable is usually the best choice f or most railing applications.

6. Spacing of cables on your end post

|

Even though you use 1x19 construction cable and the cables are properly tensioned on a strong end post, there will be some flex in the cable when a load is applied. The spacing of the cable on the end posts works together with the distance between points where the cable is supported, to minimize cable flex. The closer together the cables are spaced on the end posts, the longer the distance can be between cable support points. The reverse is also true. |

7. Whether to cut cables and put fittings on in the field or use factory cut cables.

There are three choices to consider for attaching fittings to the cables.

Cables can be:

1) Cut at the job site and the fittings attached using swageless fittings;

2) Cut at the job site and swaged on the cables using equipment and tools rented or purchased from Cable Art;

or

3) Supplied by Cable Art, cut to length with the fittings attached, ready to install.

Swageless Fittings

Swageless fittings are installed by hand in the field. No special equipment is needed, except cable cutters. (As with any method of installing, we also recommend that you use special cable gripping pliers to keep the cable from turning when you tighten the fittings to tension the cable. Cable cutters and cable gripping pliers can be provided at a low cost by Cable Art).

The first advantage is that the holes the cables pass through in your intermediate posts do not have to be any larger than is necessary for just the bare cable to pass through. If you have fittings already attached to both ends of the cable, your intermediate post holes must be at least as large as the diameter of the smallest fitting attached to the cable. The difference between the hole and cable diameters will be 1/16” or more, which will cause more cable deflection than the tighter fit obtained if the fittings are swaged on site.

The second advantage is that there is no need to provide accurate measurements to a second party who is doing the cutting and swaging of the cables. This eliminates the possibility for misinterpreting your dimensions. In the field, the cables are cut to a slightly longer length than necessary and one end fitting is attached to the cable and then attached to an end post. The cable is then strung through the railing frame. The bare end is pulled tight at the opposite end post and marked with a permanent marker for cutting. The second end fitting is attached to the cable. The cable is tensioned, and you are done. You do not have to wait for someone else to make the cables and ship them to you and take the chance that some of them may not be cut correctly. Most importantly, you are in control of when the cables are done.

Field Swaging

Field swaging offers an advantage that you do not have in using swageless fittings, in that your choice of fittings is unlimited when you field swage. Field swaging requires the use of a swaging kit and an air compressor (see our catalog or installation guide for compressor specifications) to attach the fittings to the cables. Complete instructions are included with all orders. All of the equipment necessary is available for purchase or rental from Cable Art.

Factory Swaging

If the cables are cut and the fittings swaged by Cable Art, you do not need to use special equipment. There is a charge for cutting and swaging, but for smaller jobs the cost will be less than renting the equipment required to field swage the cables. Some Cable Art hardware is designed to pass through holes in your intermediate posts that are drilled as little as 1/16” more than the diameter of the cable, when both ends are swaged by us. You will find these fittings outlined in the following section.

Where the cable will not pass through any intermediate posts, you can order factory cut and swaged cables using any hardware. You are not limited as to the fittings you can use.

8. Selection of appropriate hardware

In selecting hardware, you will need to consider: a) whether you want to field cut and swage the cables, have them factory cut and swaged, or use swageless fittings (see No. 7 Swageless Fittings); b) hardware preferences for end posts; c) how you wish to configure your corners (if applicable); d) hardware used for stairs or severe slopes.

a) Field cut and swage, factory cut and swage, or swageless fittings on the cables. See No. 7 above to determine whether you will be field cutting and swaging, if you want the factory to cut the cables and swage on the fittings, or if you will use swageless fittings.

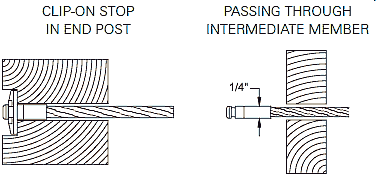

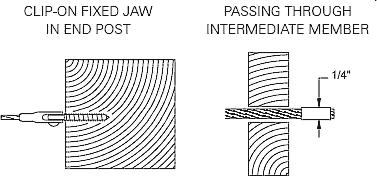

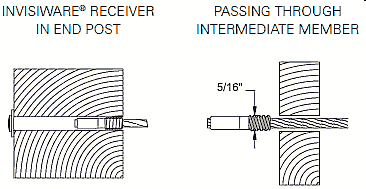

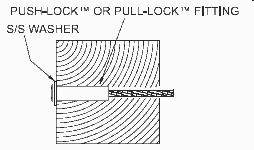

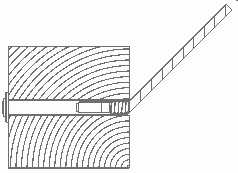

When the fittings are swaged on at the factory, some fittings are larger in diameter than the size of the holes you want to drill in your intermediate members (posts or cable braces). Our Push-Lock™ and Pull-Lock™ fittings are attached to the bare end of the cable after the cable is passed through your intermediate members, so you need to drill your intermediate post holes only large enough for the cable to pass through, if you use that fitting. The fittings illustrated below, however, require slightly larger holes in your intermediate members for the fittings to pass through.

If the hardware is swaged on at the factory and if the cable will pass through intermediate posts or cable braces, one end of each cable should have one of the following fittings.

The holes in your intermediate member will be drilled for the diameter of the swaged fitting passing through the intermediate member as shown in the following illustrations:

Field cut and swage, factory cut and swage, or swageless fittings on the cables. See No. 7 above to determine whether you will be field cutting and swaging, if you want the factory to cut the cables and swage on the fittings, or if you will use swageless fittings.

When the fittings are swaged on at the factory, some fittings are larger in diameter than the size of the holes you want to drill in your intermediate members (posts or cable braces). Our Push-Lock® and Pull-Lock® fittings are attached to the bare end of the cable after the cable is passed through your intermediate members, so you need to drill your intermediate post holes only large enough for the cable to pass through, if you use that fitting. The fittings illustrated below, however, require slightly larger holes in your intermediate members for the fittings to pass through.

If the hardware is swaged on at the factory and if the cable will pass through intermediate posts or cable braces, one end of each cable should have one of the following fittings.

The holes in your intermediate member will be drilled for the diameter of the swaged fitting passing through the intermediate member as shown in the following illustrations:

|

Clip-On Stop |

|

|

||

|

Clip-On Fixed Jaw |

|

|

||

|

Invisiware® Receiver |

Where the cable will not pass through any intermediate members, you can order factory cut and swaged cables using any hardware. You are not limited to the fittings shown above.

If you will be using swageless fittings or field swaging to attach to the cables, you need to drill your intermediate post holes only large enough for the cables to pass through the posts.

If your cables will be cut and the fittings swaged on by Cable Art, you will need to provide Cable Art with measurements for your cable runs after the posts have been installed. Contact Cable Art or visit the website for the Measurement Worksheets required for factory cutting.

b) Mounting hardware on your end posts.

If you are mounting hardware on two sides of your corner posts, then your corner posts are considered end posts for this discussion.

You will need to put tensioners on at least one end of each cable run. Following are tensioning devices

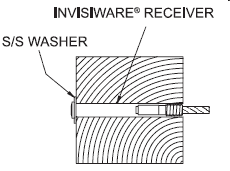

|

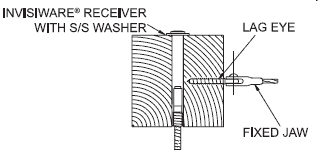

Invisiware® Receiver |

|

|

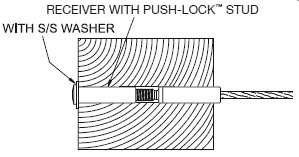

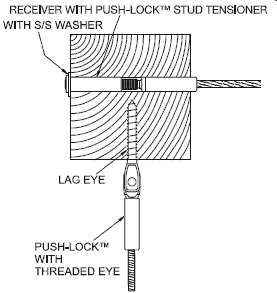

Reveiver with Push-Lock™ Stud 1/8" |

Note: With the Invisiware ® Receiver or Receiver with Push-Lock™ stud tensioner, you will need up to 3-3/4” of space between the back of your end post and any structure to insert the fitting into the end post from the back side.

|

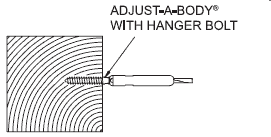

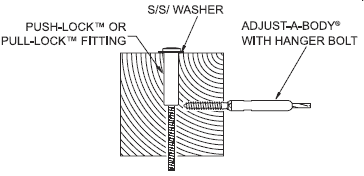

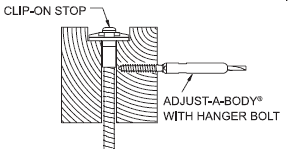

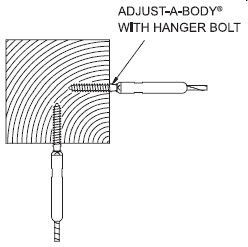

Adjust-A-Body® with Hanger Bolt |

|

|

||

|

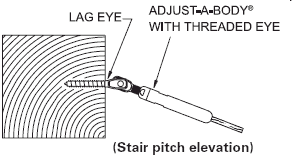

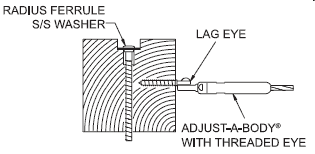

Lag-Eye Adjust-A-Body® with Threaded Eye |

|

|

||

|

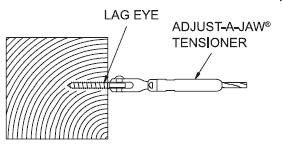

Adjust-A-Jaw |

The other end of each cable run can be either a tensioner (above) or a non-tensioning device. Following are non-tensioning devices.

|

Pull-Lock™ 1/8" |

|

|

||

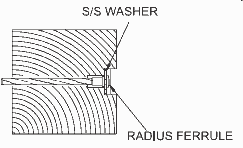

|

Invisiware® Radius Ferrule |

Note: With the Radius Ferrule, Push-Lock™ or Pull-Lock fittings, you will need approximately 2-1/2” of space between the back of your end post and any structure to insert the fiting into the end post from the back side.

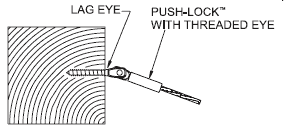

|

Lag-Eye Push-Lock™ With Threaded Eye 1/8" |

|

|

||

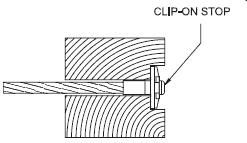

|

Clip-On-Stop |

|

|

||

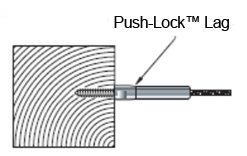

|

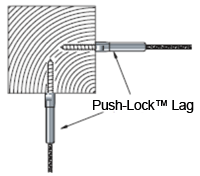

Push-Lock™ Lag |

|

|

||

|

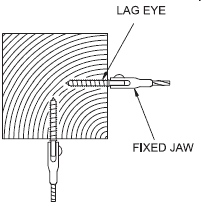

Fixed Jaw Lag-Eye |

c) How you wish to configure your corners (if applicable).

See No. 2. Configuration of any corners in your design above for ways to treat your corners.

The following illustrations demonstrate how the hardware can be used on a single corner post. They also illustrate how some hardware can be countersunk into the post or mounted flush with the back of the post. Not all combinations are shown here. If the hardware and cable run all the way through the post in one direction, you will need to use a hanger bolt end or hardware that is mounted to a lag eye for the perpendicular direction, as shown in the first five illustrations that follow.

|

Pull-Lock™ 1/8" Adjust-A-Body® With Hanger Bolt |

|

|

||

|

Receiver with Push-Lock™ Stud 1/8" Lag-Eye Push-Lockx™ With Threaded Eye 1/8" |

|

|

||

|

Invisiware® Receiver Lag-Eye Fixed Jaw |

|

|

||

|

Clip-On-Stop Adjust-A-Body® With Hanger Bolt |

|

|

||

|

Invisiware® Radius Ferrule Lag-Eye Adjust-A-Body® With Threaded Eye |

|

|

||

|

|

|

|

||

|

Lag-Eye Adjust-A-Jaw® Tensioner |

|

|

||

|

Push-Lock™ Lag |

d) Hardware used for stairs or severe slopes.

You can use any of the fittings with a fork or an eye in conjunction with a Lag Eye, to accommodate stairs and slopes. These fittings are Adjust-A-Jaw® , Adjust-A-Body® with Threaded Eye tensioners, Fixed Jaw and Push-Lock™ with threaded eye non-tensioning fittings.

On pitches up to 35°, you can also use P/N 20F4062 Invisiware® Receivers on your 4x4 (3.5” square) end posts without having to drill your holes at an angle.

|

Invisiware® Receivers are less expensive than fittings with fork or eye ends and do not require lag eyes and screws to mount them. When installed, they are hidden inside the end post to help preserve that special view. 20F4062 Invisiware® Receivers are especially designed for 4x4 wood posts and can be an excellent choice for stairs and slopes as well as straight runs. |

Conclusion

Cable as a railing in-fill can be attractive, easy to install and virtually maintenance free. Understanding the above considerations when designing your cable railing will go a long way toward insuring that code requirements are met with a railing that you and/or your customer will be proud of.